LAFER

LAFER S.P.A.

Via Lago di Garda, 98 - 36015 SCHIO (VI)

Tel: +39 0445 694320

E-mail: sales@laferspa.com

Web: www.laferspa.com

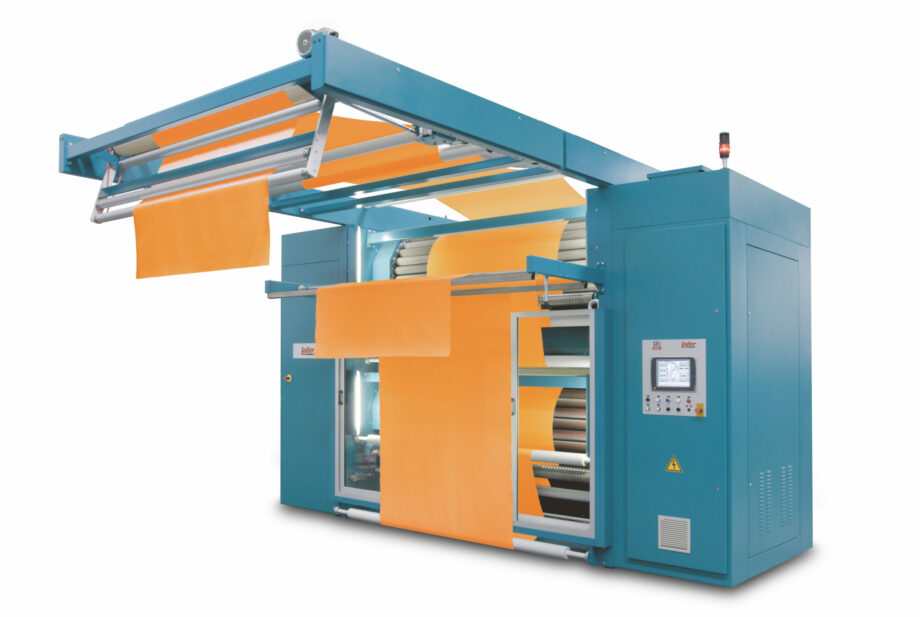

Lafer’s objective is to create finishing machines with premium build quality that control fabrics with the highest precision.

Together with mechanical engineering, Lafer’s in-house electronic and software development team always strive for more advanced integration of moving parts, electronics and operating software.

– Lafer raising machines have the highest productivity.

– Shearing machines have custom made shearing groups to maximize cutting precision.

– Various versions of felt compactors also integrated with mechanical metal shoe type compacting modules maximize setting precision of compaction action and preserve the original 3D knit fabric appearance or if preferred a rubber belt sanforizing unit will give a flatter look with more lustre.

– Lafer supplies different versions of sueding machines for knits and wovens for finer or more dense (warmer) effects.

Various wet finishing processes have also been developed:

– Wet sueding for the smoothest (cleanest) effect.

– Open width enzyme treatment for a more uniform and effective results than rope form processing.

– Closed loop waterless scouring for 100% synthetic stretch fabric with zero discharge

– Liquid ammonia mercerizing with versions for knits and wovens. Lafer continues to seek the most precise control of fabric tension management, finishing parameters and transport to improve quality.

Production

- 7.1.5 Fringeing machines

- 8.1.11 Solvent washing machines

- 8.1.14 Mercerising machines for woven and knitted fabrics

- 8.4.15 Felt calenders

- 8.5.3 Decatising machinery

- 8.5.4 Raising machines

- 8.5.5 Tigering machines

- 8.5.6 Polishing machines

- 8.5.7 Shearing machines

- 8.5.9 Suede finishing machines

- 8.5.10 Brushing machines

- 8.5.12 Pile finishing machines

- 8.5.15 Calenders

- 8.5.26 Shrinking machines